Steam Turbines

Today, the demand for energy-efficient and eco-friendly solutions is more critical. Industries face the challenge of reducing their environmental impact while meeting growing energy needs. This balance often drives companies to find ways to optimize resources and minimize waste. As a result, new solutions are transforming power generation management, boosting efficiency, and fostering sustainability.

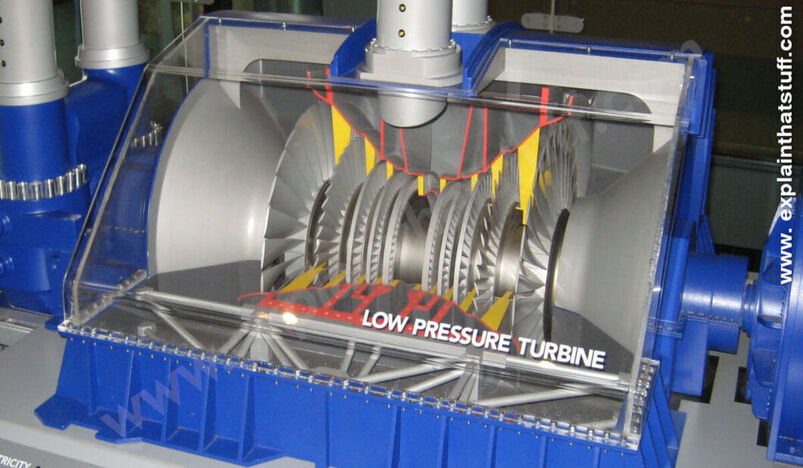

One such innovative solution is the use of advanced technologies in industrial applications to reduce waste. Among these, the integration of steam turbines has emerged as a game-changer across various industry segments. These steam turbines capture the maximum energy from steam, converting it into power while minimizing resource wastage.

Maximizing Energy Efficiency

Steam turbines enhance waste reduction by extracting maximum energy from steam. Condensing steam turbines, for instance, effectively utilize inlet steam, enabling power generation with minimal waste. Products such as controlled extraction and double extraction condensing models are especially useful in industrial segments where both power generation and steam are required to meet both electricity and heating requirements.

Supporting Waste-to-energy Applications

The global push towards sustainable practices has led to a growing interest in waste-to-energy technologies. Steam turbines play an important role in converting waste materials into usable energy. They offer industries a way to reduce their environmental impact and generate power. In waste-to-energy plants, steam turbines help convert thermal energy from incinerated waste into electricity, reducing the need for landfills and providing a sustainable power source.

Reduced Steam Leakages and Enhanced Performance

Modern steam turbines minimize steam leakages with high efficiency sealing systems, preventing significant energy losses and reducing operational waste. This ensures industries maximize their steam supply and improve overall energy efficiency.

Designed for long-term performance, the condensing steam turbines utilize innovative features and advanced materials for enhanced durability. Regular maintenance and upgrades also support waste reduction by keeping steam turbines operating efficiently throughout their lifecycle.

Customized Solutions for Diverse Industries

Steam turbines are highly adaptable to various industrial sectors and can be customized for specific power and process requirements. For instance, backpressure steam turbines are used in industries needing both electricity and process steam, while condensing steam turbines are used mainly for power generation applications. This adaptability helps optimize energy use, reduce waste, and lower carbon footprints.

Promoting a Greener Future

In light of increasing global efforts to combat climate change, steam turbines also support the transition towards a greener and more sustainable future.

Steam turbines are a proven technology in traditional power generation and play a pivotal role in supporting low-carbon footprint initiatives.

Driving Sustainability with Steam Turbines

As industries place greater emphasis on sustainability, steam turbines play a crucial role in optimizing energy usage and reducing environmental impact. Their versatility ensures that power generation remains both cost-effective and eco-friendly, enabling businesses to lower carbon emissions while maintaining operational efficiency.

To fully capitalize on the benefits of this technology, companies should partner with trusted steam turbine manufacturers like Triveni Turbines. Partnering with experienced companies that have over 50 years in the industry offer not only tailor-made products but also efficiency improvements and upgrading services.

1. How do steam turbines enhance energy efficiency?

Steam turbines maximize energy efficiency by capturing and converting the maximum amount of energy from steam into usable power. This is achieved through advanced technologies like condensing steam turbines, which minimize waste and ensure optimal use of steam for electricity and heating.

2. What role do steam turbines play in waste-to-energy applications?

Steam turbines are crucial in waste-to-energy plants, where they help convert thermal energy from incinerated waste into electricity. This process reduces the need for landfills, minimizes environmental impact, and provides a sustainable power source by utilizing waste materials.

3. How do modern steam turbines minimize waste?

Modern steam turbines are designed with high-efficiency sealing systems that reduce steam leakages, preventing energy losses. This design improves the overall energy efficiency of industrial operations, allowing companies to maximize their steam supply and reduce waste.

4. What are condensing steam turbines, and how do they help reduce waste?

Condensing steam turbines extract maximum energy from steam by efficiently utilizing the inlet steam. These turbines are particularly beneficial for industries that require both power generation and heating, as they help optimize energy use and minimize resource wastage.

5. Can steam turbines be customized for different industries?

Yes, steam turbines can be tailored to meet the specific needs of various industries. For example, backpressure steam turbines are ideal for industries that require both electricity and process steam, while condensing steam turbines are best suited for power generation, helping reduce waste across sectors.

.jpg)

Qatar Secures Place Among the World's Top 10 Wealthiest Nations

.jpg)

Hamad International Airport Witnesses Record Increase in Passenger Traffic

Saudi Arabia: Any visa holder can now perform Umrah

What are Qatar's Labour Laws on Annual Leave?

Leave a comment